Plc ile Kutuların Uzunluğuna Göre Ayırma Projesi:

Separation Project of Boxes According to Length with PLC:

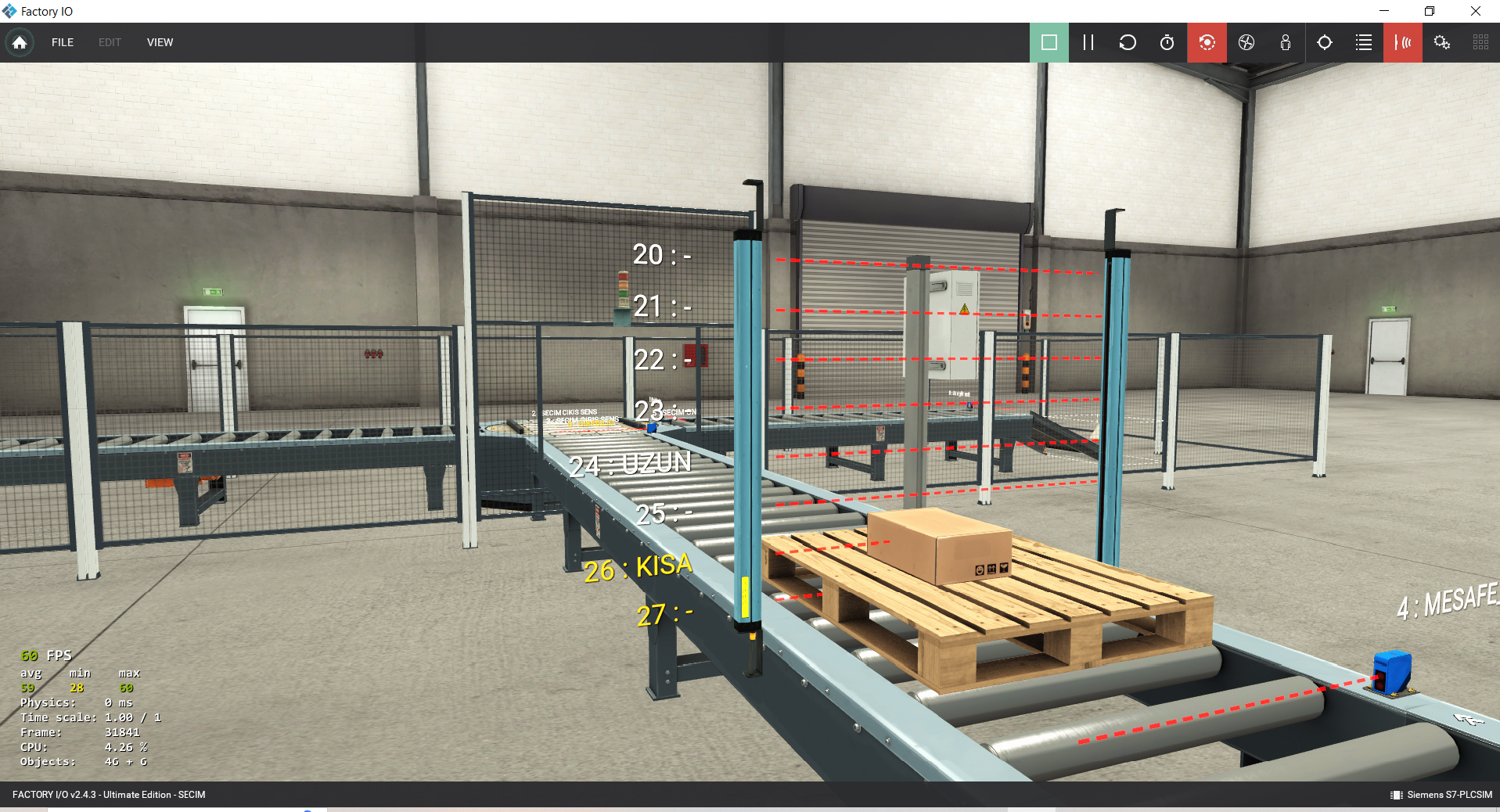

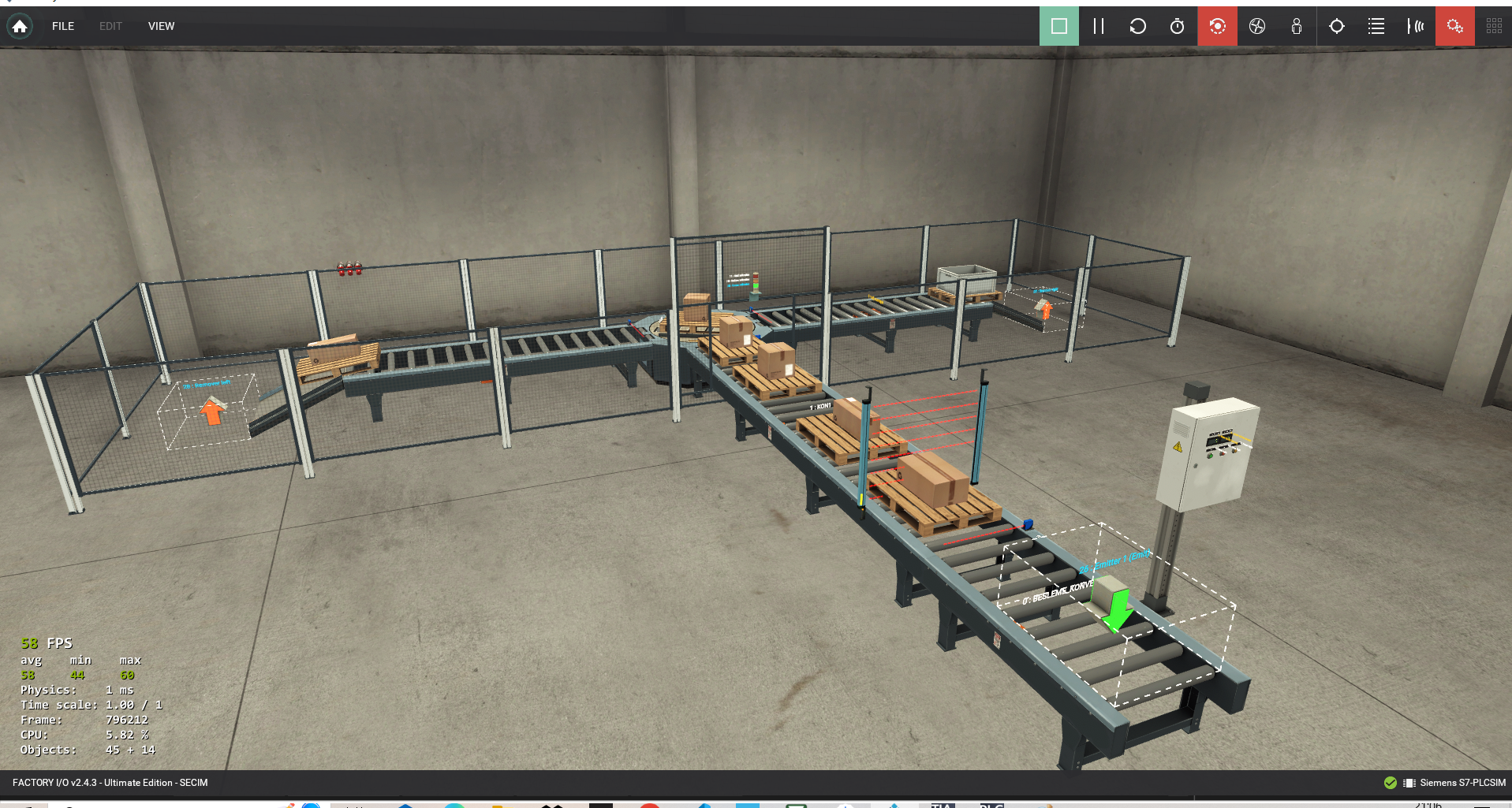

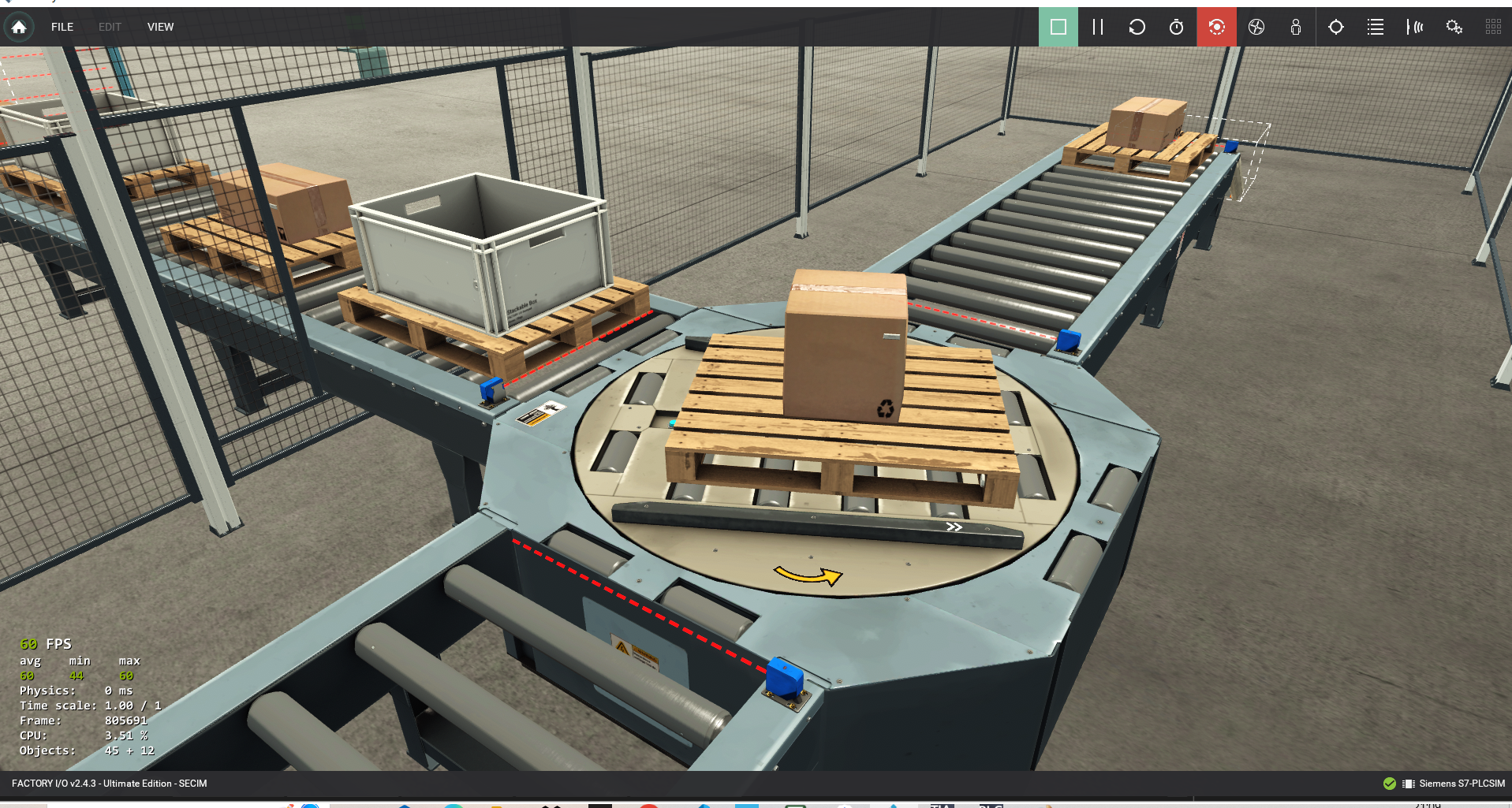

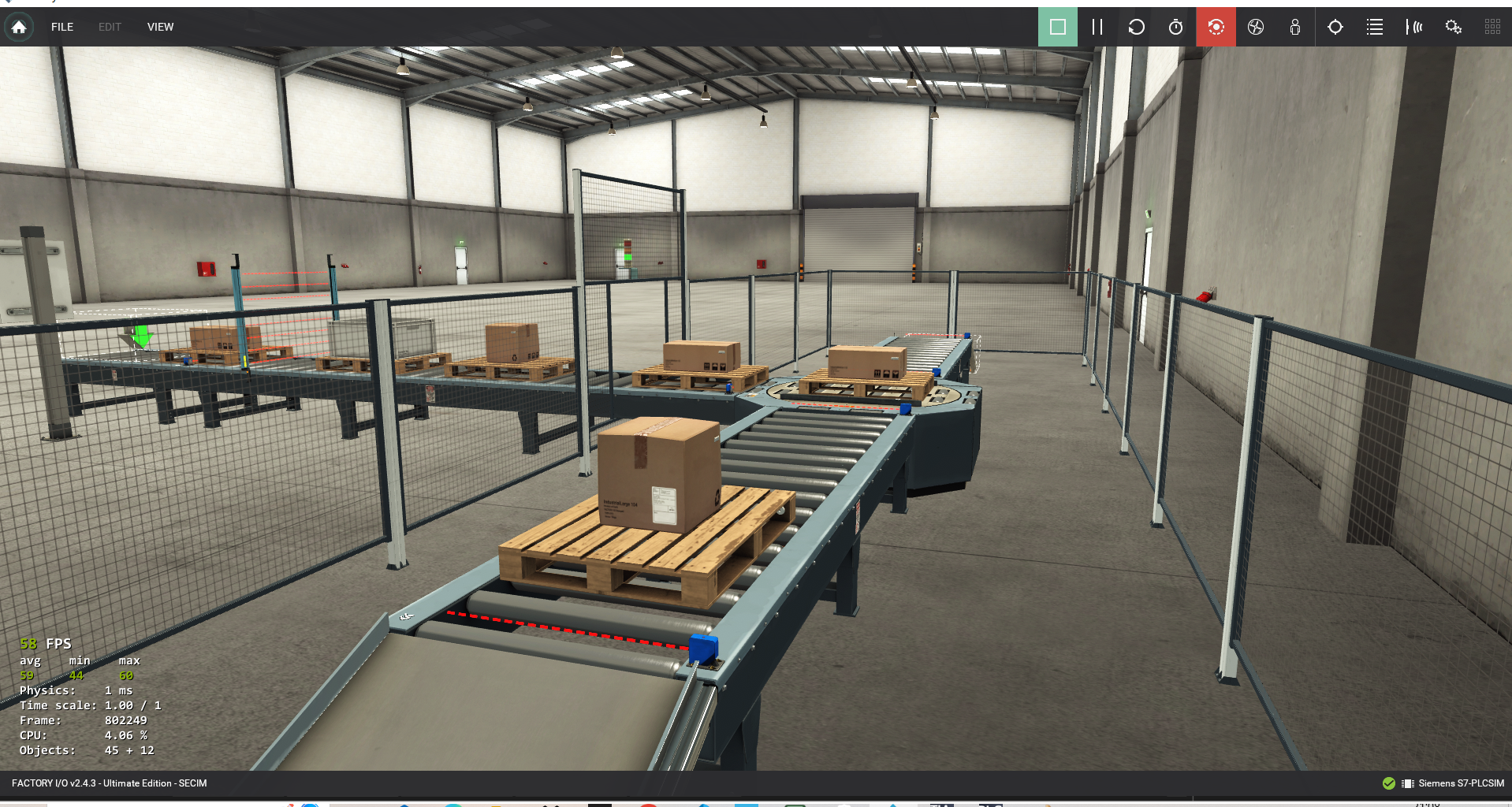

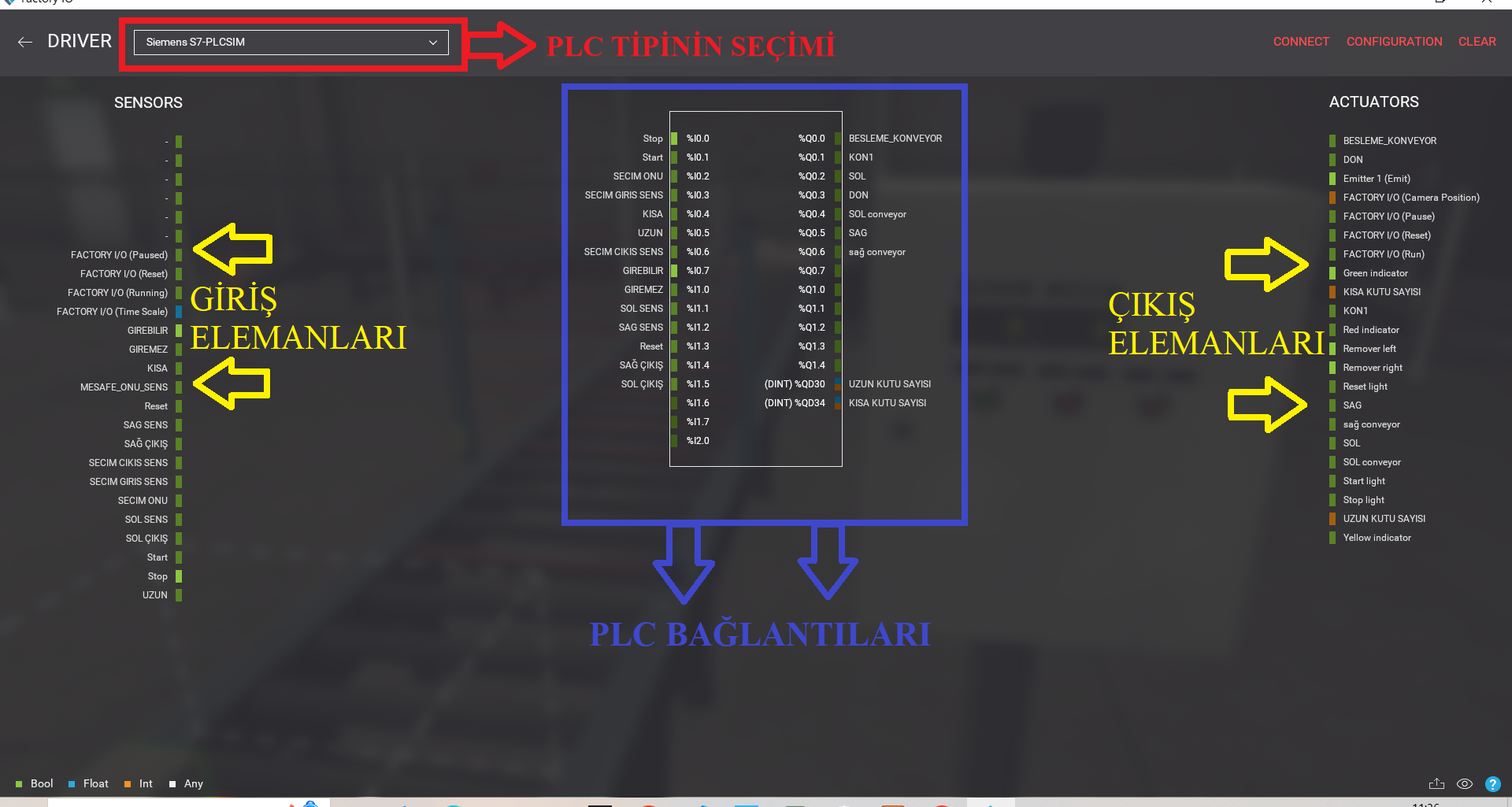

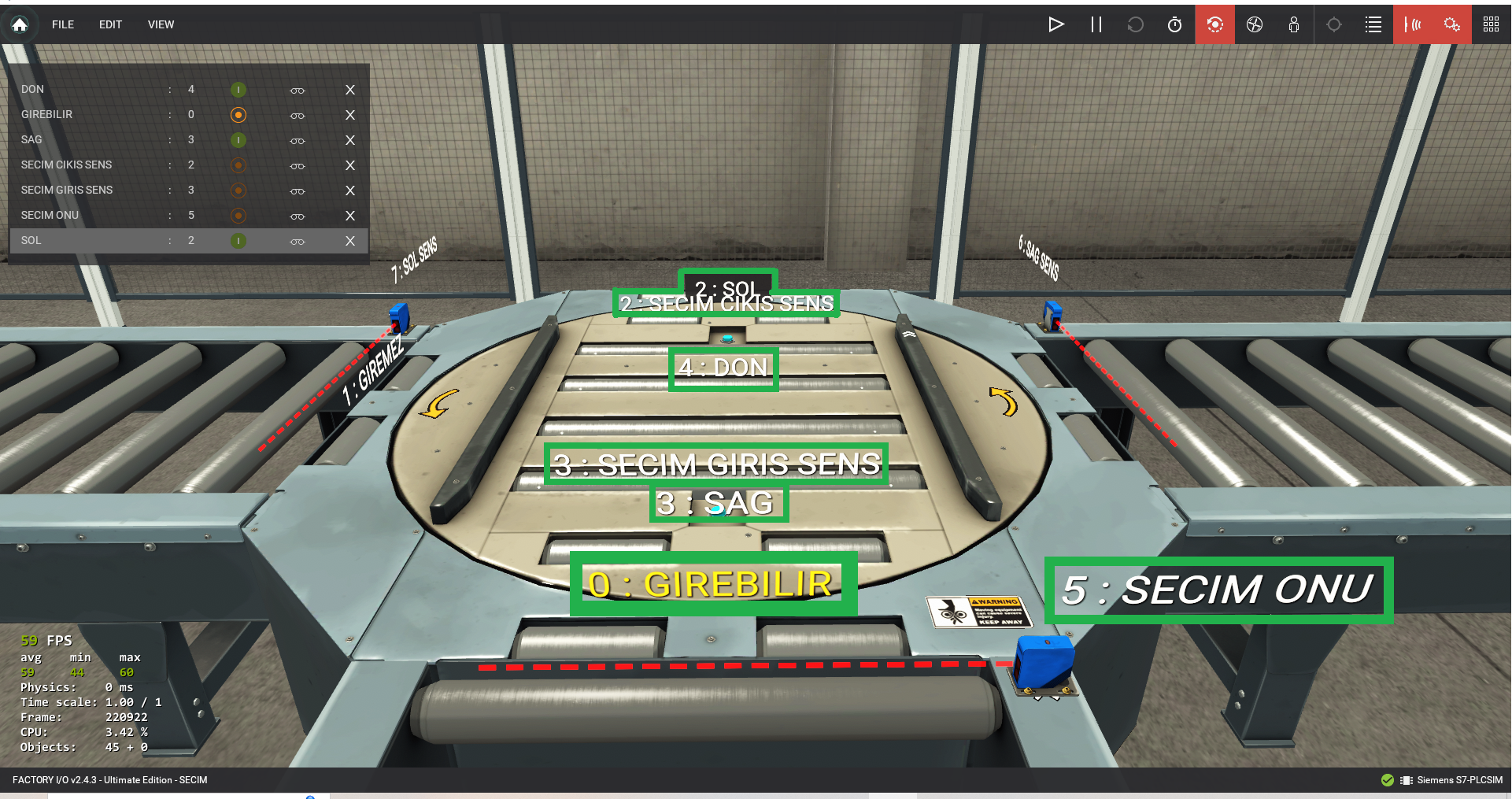

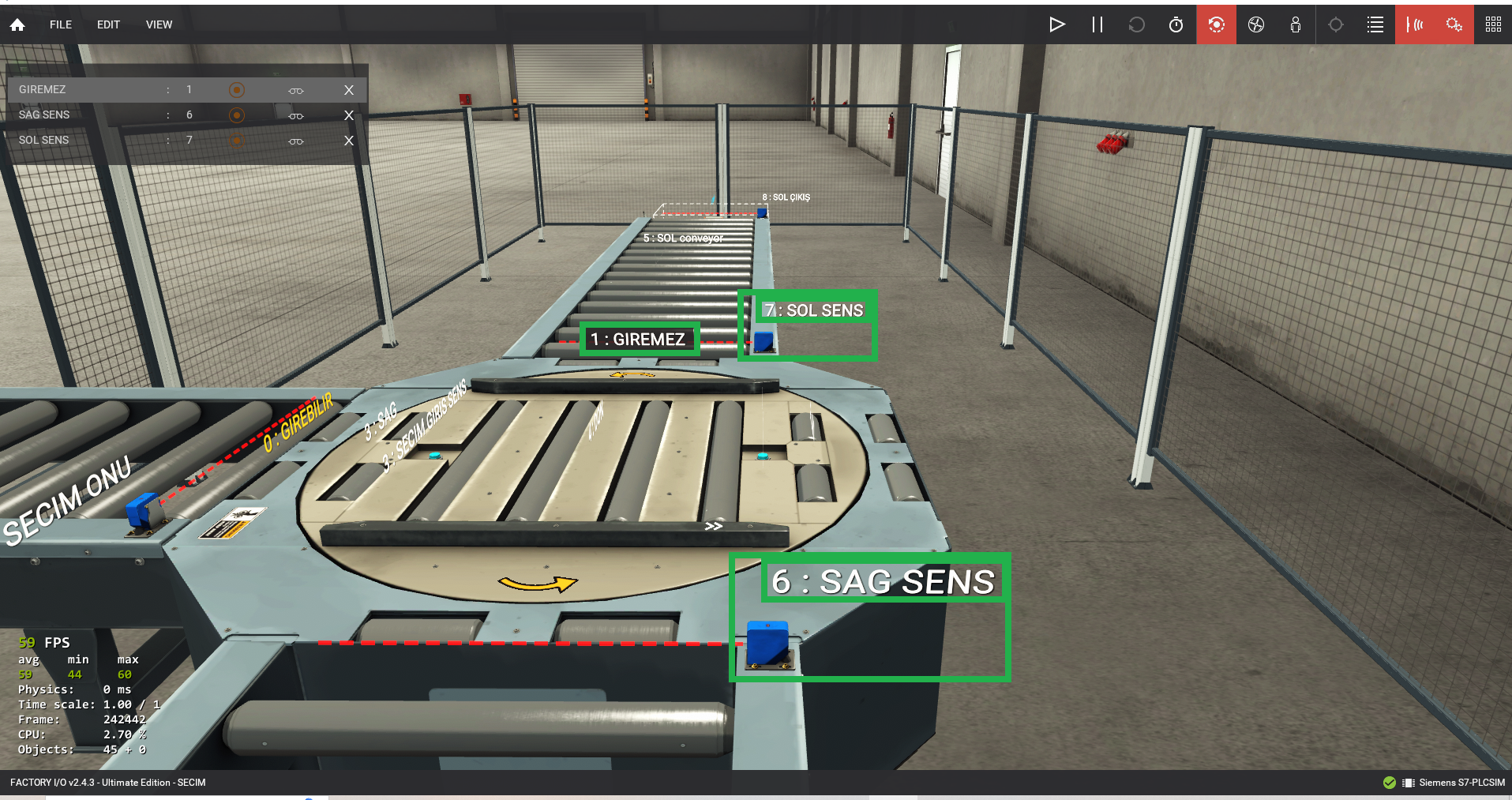

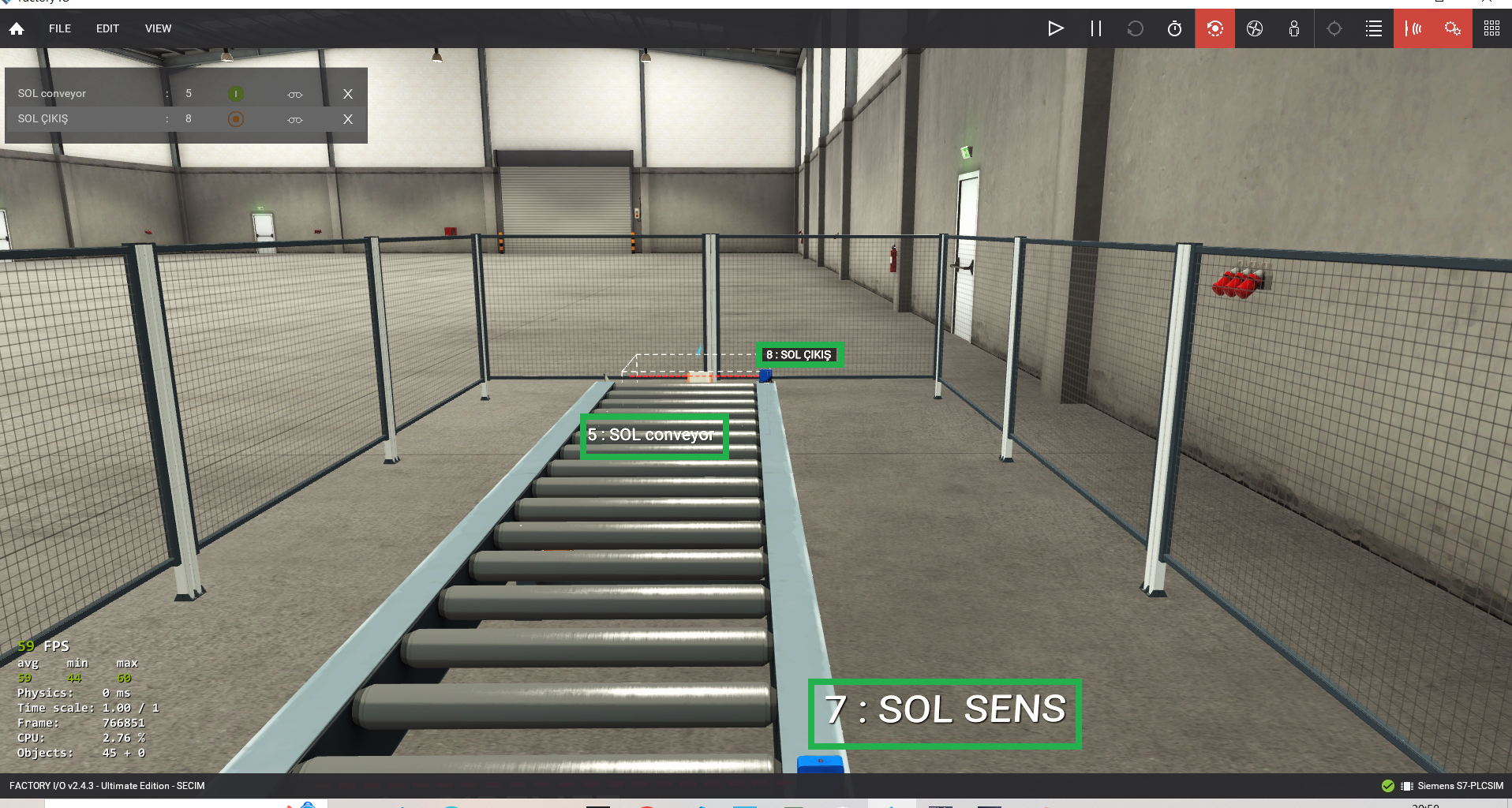

➤ In the images above you can see the project design, the names of the connections and the Factory-io driver menu in detail.

# Ladder and Scl programming languages were used in this project.

Things used in Tia Portal Program

• CPU 1211C DC/DC/DC.

• Main block, Data block, and Function block.

• Time relay TON.

• Move command.

• Counters CTU.

• Positive edge-triggered contacts.

• Comparison contacts.

• DWorld, World, DInt, Bool, Real, PLC tags.

• I, Q, M, QD addresses.

Things used in Factory-io program

• Start button.

• Stop button.

• Reset button.

• Two DINT displays.

• Six retro-reflective sensors.

• Light barrier (digital).

• Four conveyors.

• Rotating table.

System Operation

• When the start button is pressed,

• Boxes of different sizes come from the entrance.

• The project begins with a light barrier at the beginning of the conveyor. This light barrier detects the height of the box passing over it. Depending on the box's height, it is classified as long or short.

• Information about whether the box is long or short is transferred to the data block inside the record name in the PLC.

• Using the function block named "record" in the PLC, if the box is long, it is recorded as number 1, and if the box is short, it is recorded as number 2 for later use.

• The pre-selection sensor ensures that only one box passes over the rotating table. The second box cannot pass.

• Depending on their height classification, the boxes are directed to the appropriate conveyor via the rotating table. If the box is long, it is directed to the right, and if it is short, it is directed to the left.

• The rotating table is used to direct the boxes to separate conveyors. The table's movement is controlled based on the box's height.

• The boxes are directed to separate conveyors. Both conveyors are equipped with sensors at their ends. As the boxes pass these sensors, they are counted.

• At the same time, the number of boxes transferred to the left and the number transferred to the right can be monitored in real-time on the panel.

• If desired, values can be reset via the reset button on the panel.

• The operation can be stopped at any time using the "stop" button on the panel.

Project Benefits

- Reduces human intervention and enables an automated box sorting and counting process.

- Increases efficiency and minimizes the probability of errors.

- Facilitates the easy classification and counting of boxes of different sizes.

Conclusion

Automation projects are of great importance in every field of industry. This automatic bin sorting and counting system simplifies a complex process and brings speed and precision to businesses. Such projects provide an example of how automation will gain more functions in the future and help manage industrial processes efficiently.

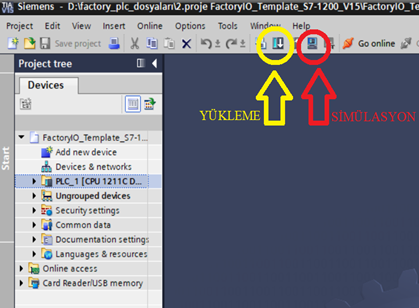

Connection Settings of PLC and Factory-io program

• Download the Factory I/O template file.

• Create the PLC program.

• Run the simulation in TIA Portal software.

• Then, create the system in the Factory I/O program.

• Go to the driver settings menu from the File menu.

• Choose Siemens S7-PLCSIM as the PLC type.

• Select 1200 PLC from the configuration settings.

• Then, click on 'Connect' to establish a connection.

Tia Portal Software

Below is the Tia Portal software. The contact names in the Tia Portal must match the Factory-io program, otherwise it will not work.