Plc ile Ağırlığa Göre Ayırma, Paletin Üzerine Dizme ve Raflama Projesi:

Sorting by Weight with PLC, Arranging on Pallets and Shelving Project:

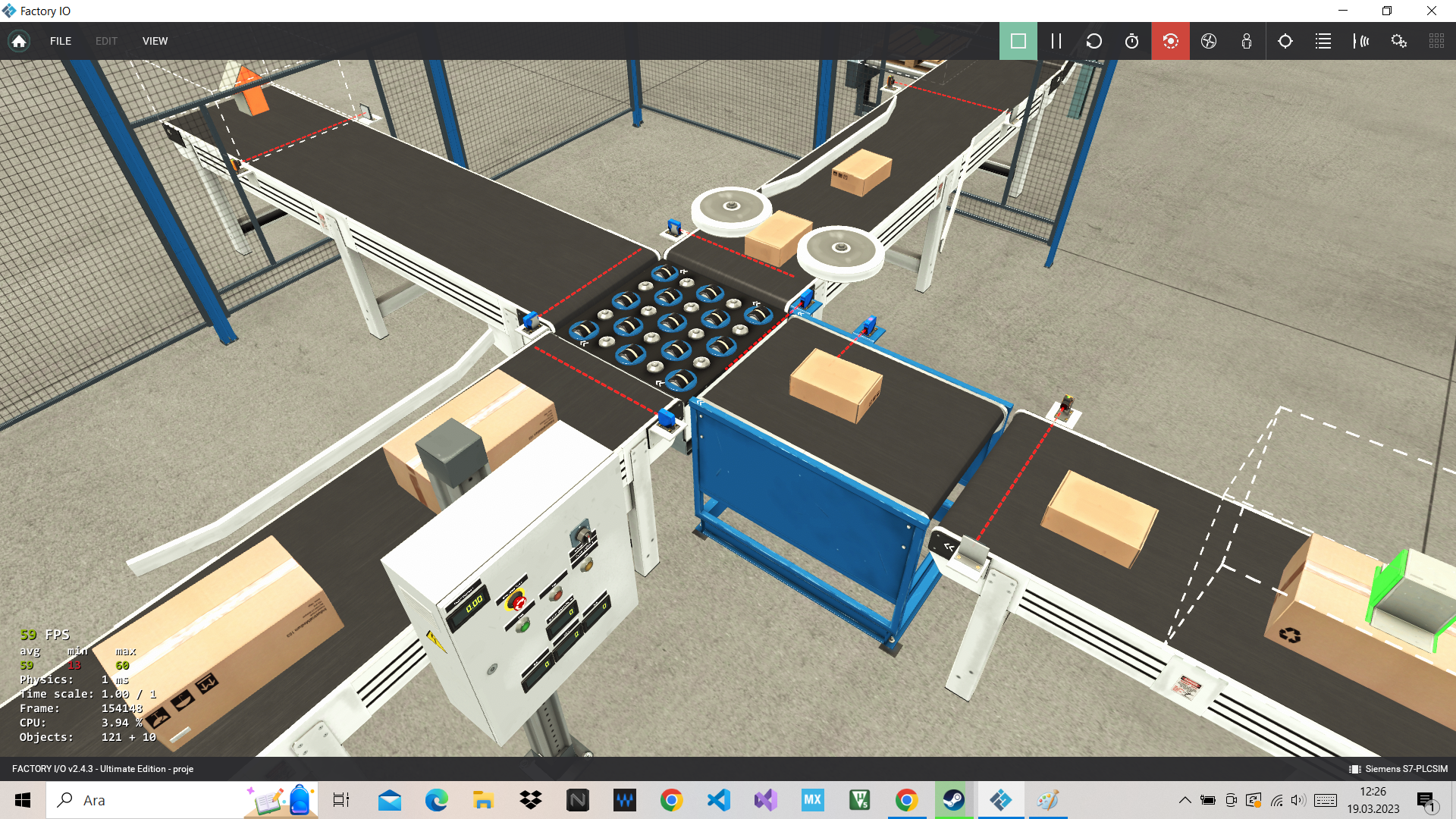

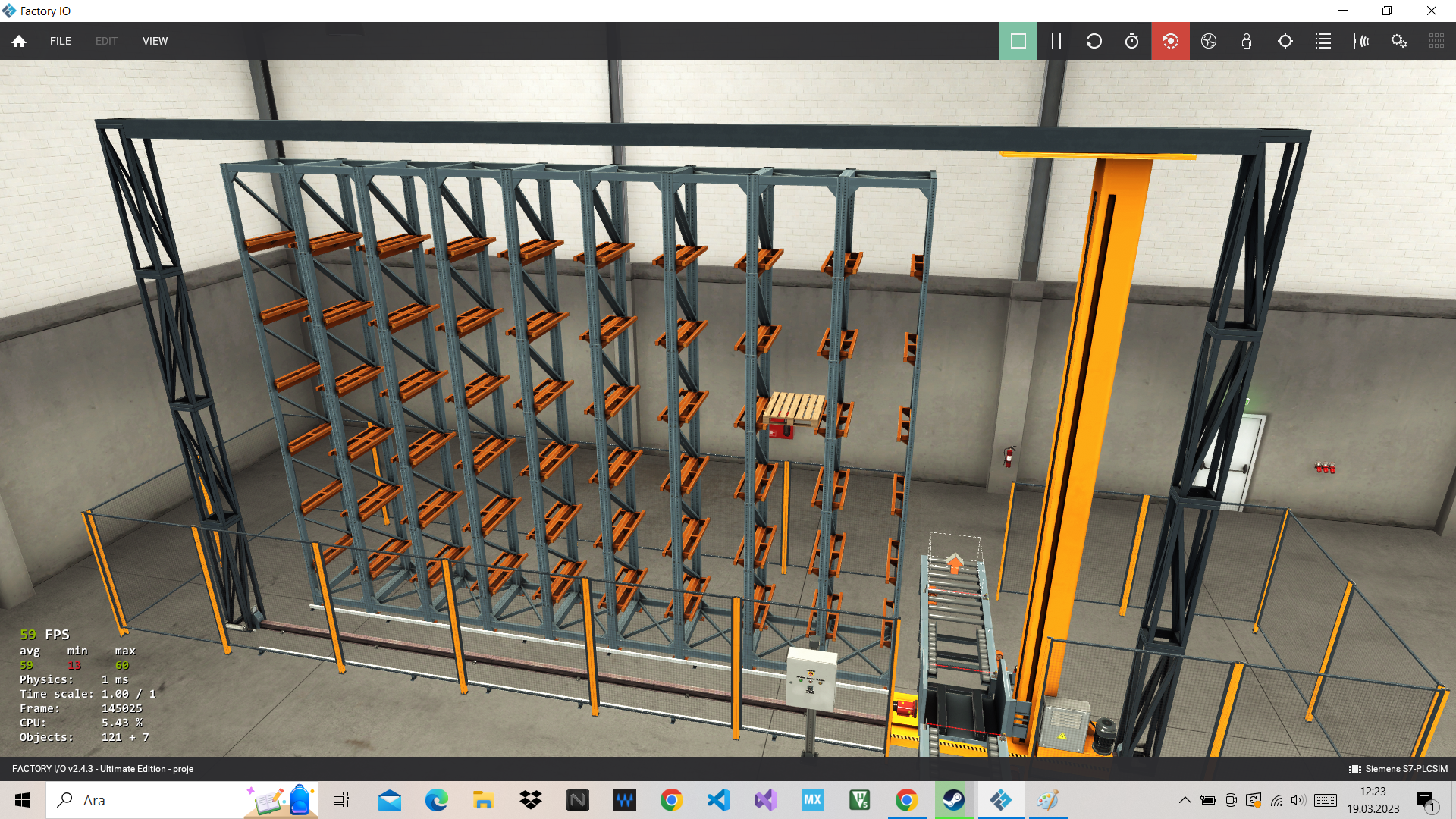

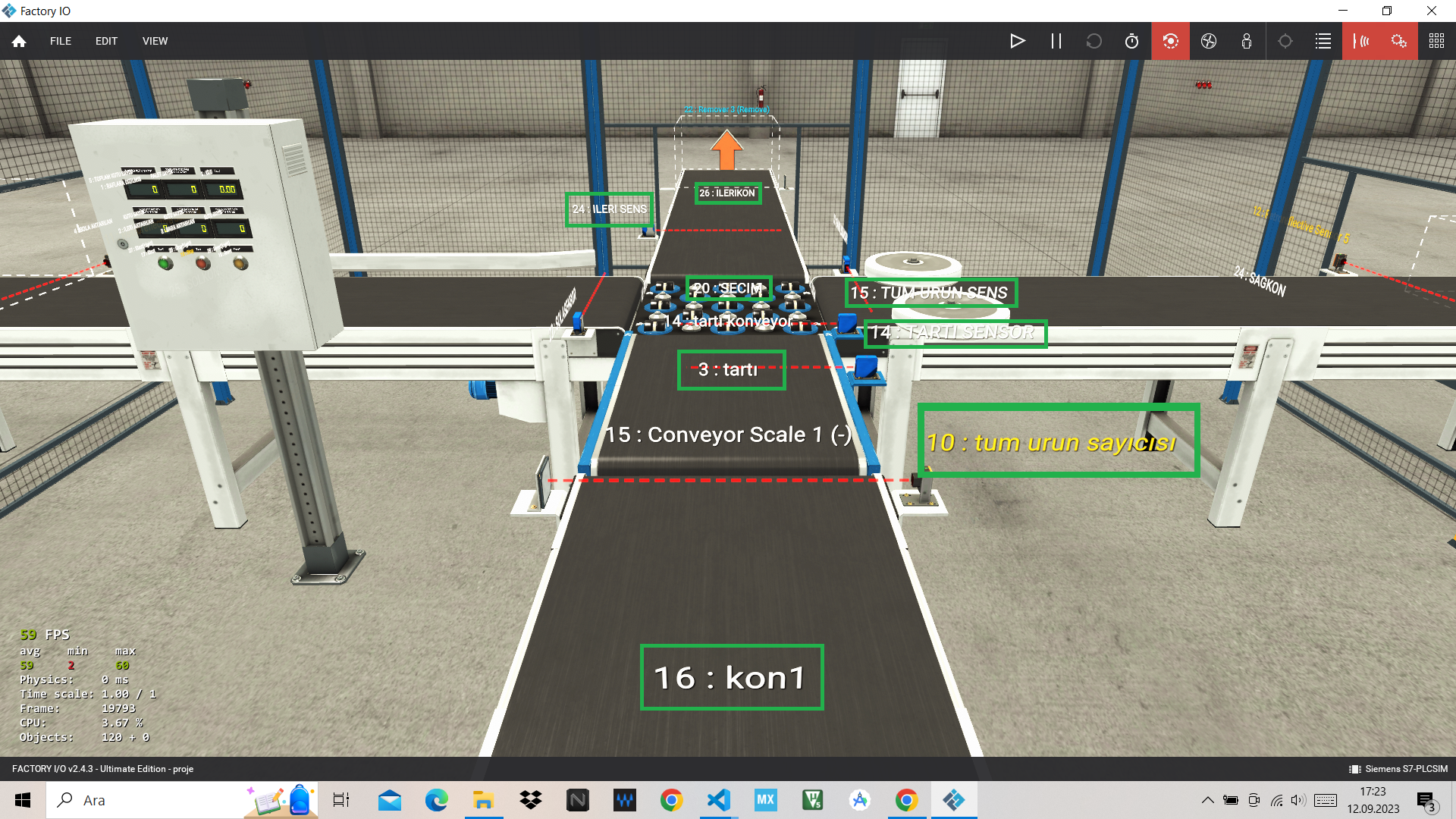

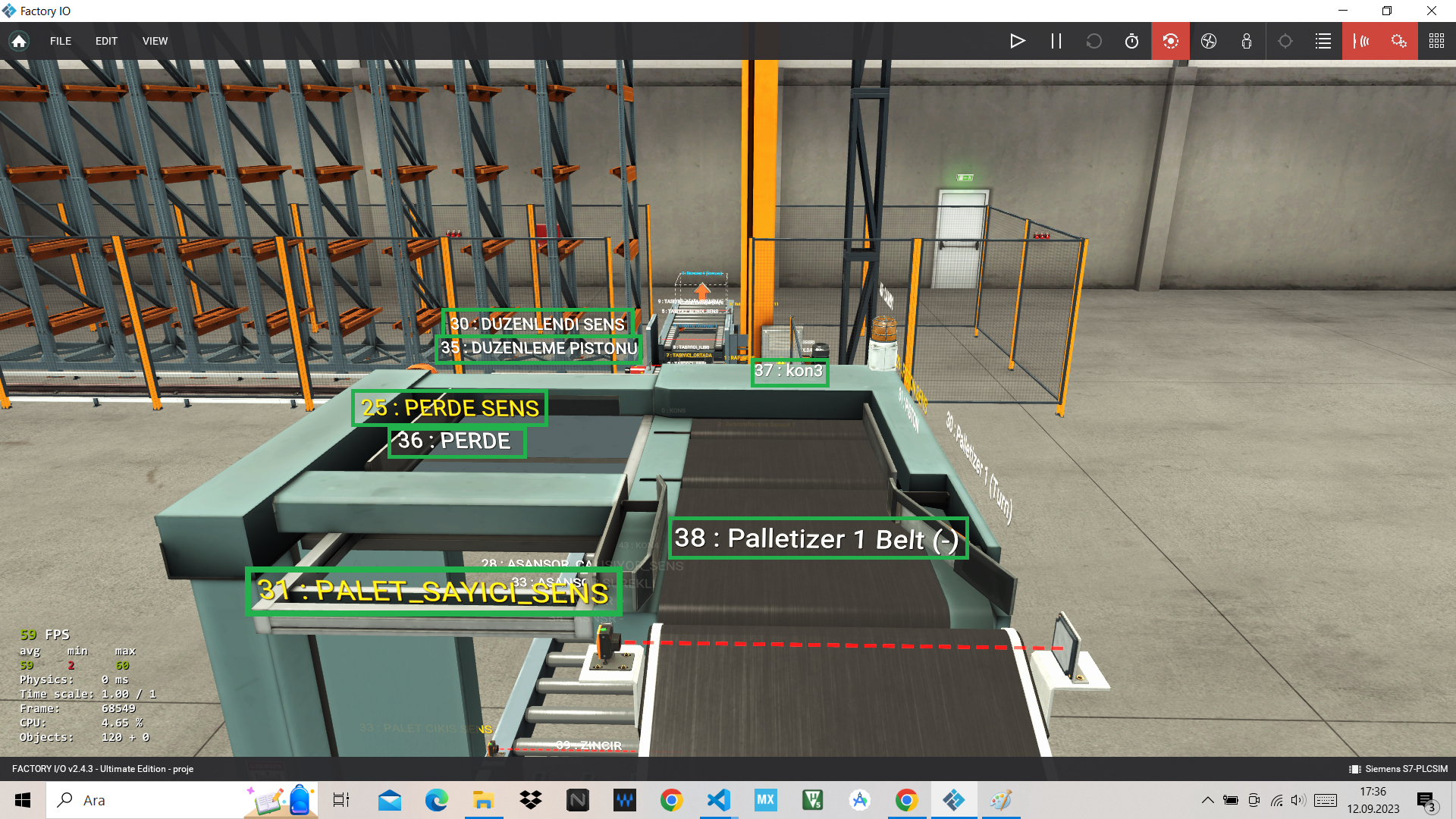

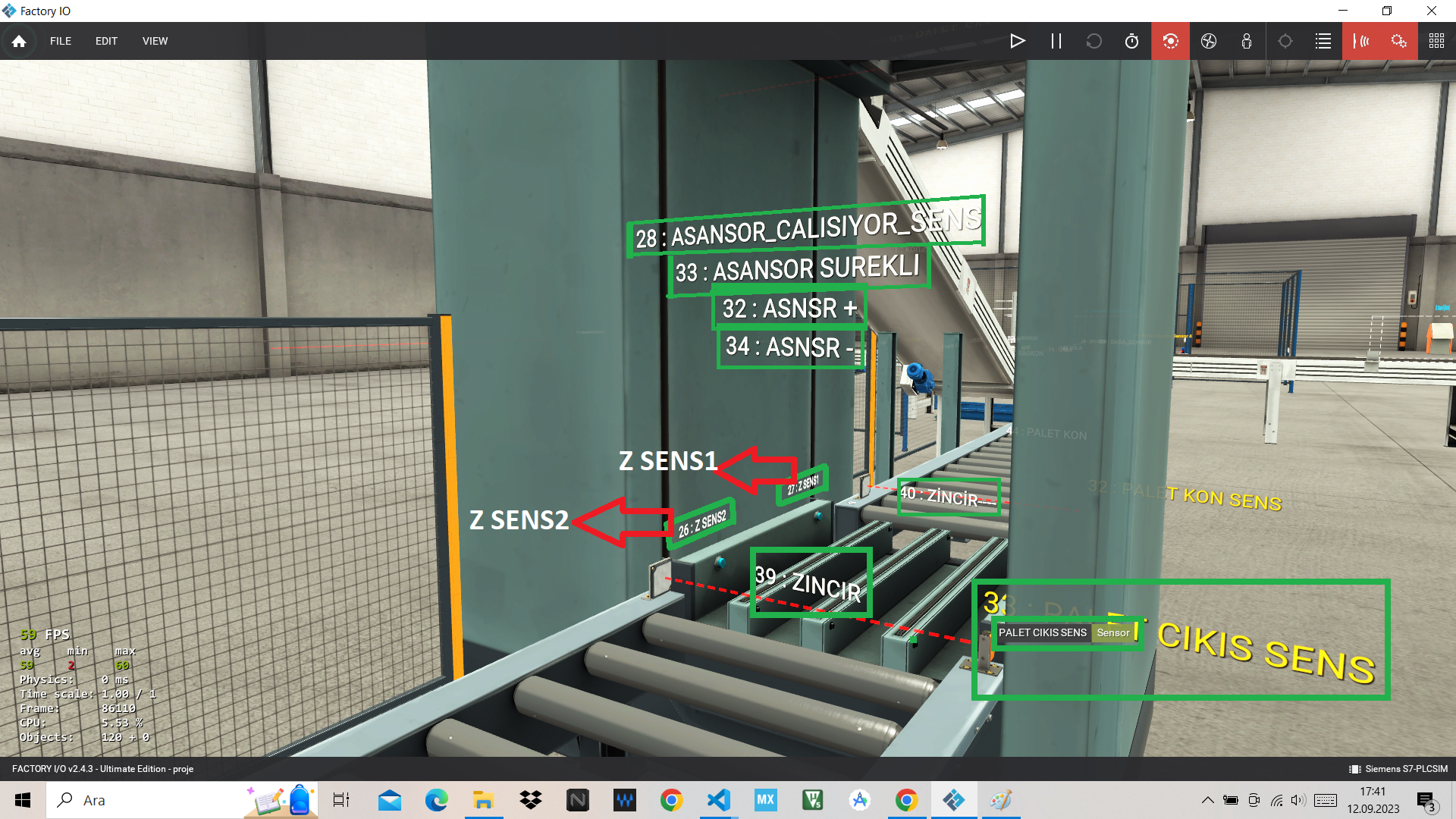

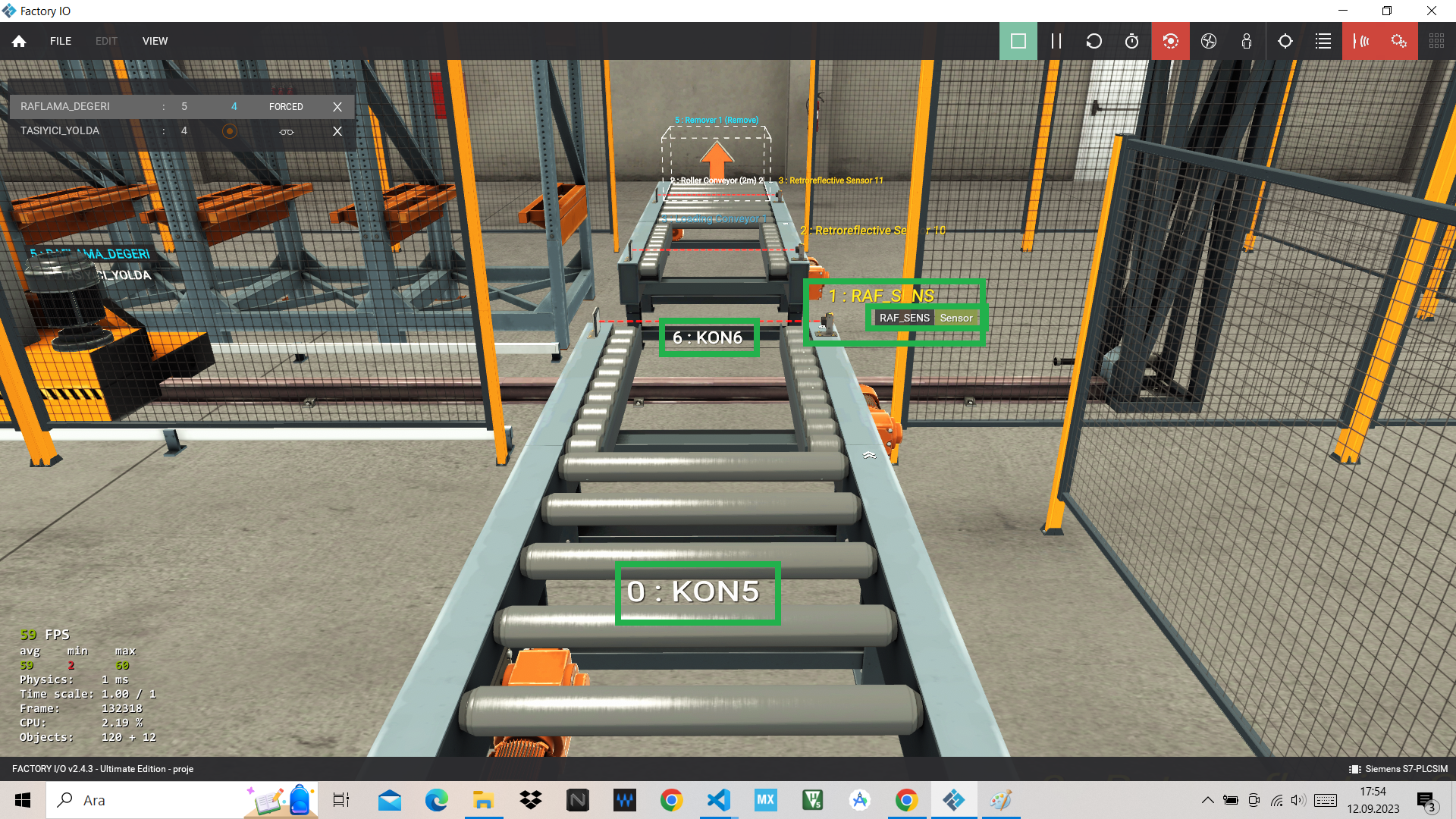

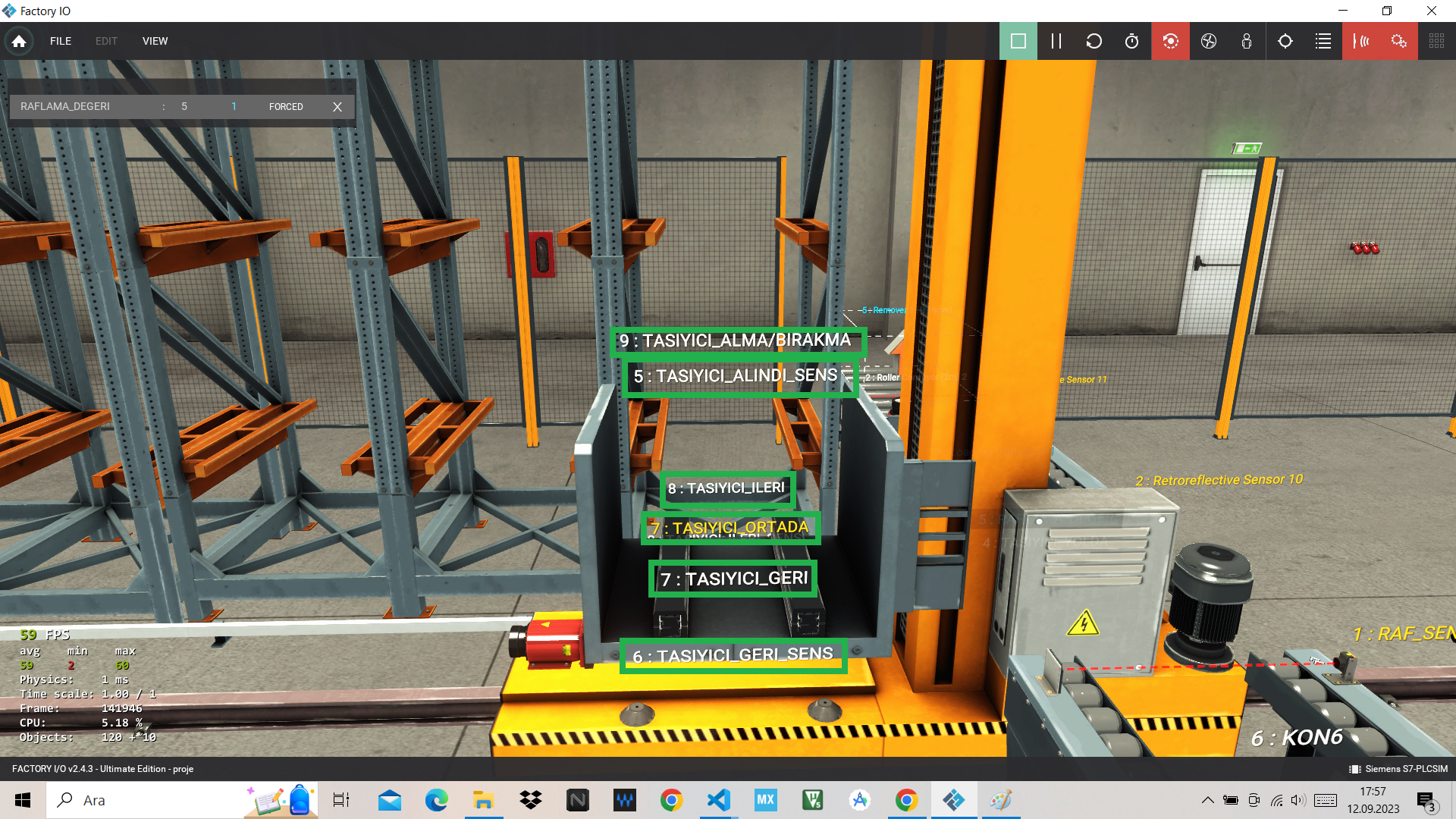

➤ In the images above you can see the project design, the names of the connections and the Factory-io driver menu in detail.

Things used in Tia Portal Program

• CPU 1211C DC/DC/DC.

• Main blok and data blok.

• Time relay TON and TOF.

• 'Move' command.

• Counters.

• Positive and negative edge triggered contacts.

• Comparison contacts.

• Mathematical functions.

• Clock contacts.

• DWorld, World, DInt, Bool, Real, plc tags.

• I, Q, M addresses.

Things used in Factory-io program

• Start button.

• Stop button.

• Reset button.

• Five DINT indicators.

• One REAL indicator.

• Five retro-reflective sensors.

• Six photoelectric sensors.

• Nine conveyors.

• Pneumatic separator.

• Two regulating wheels.

• Start, stop, reset, and palletizing lights.

• Palletizing system.

• Racking system.

• Palletizing chain.

System Operation

• When the start button is pressed,

• Boxes of different sizes and weights come from the entrance,

• The first sensor allows only one box to pass over the scale and prevents the passage of the second box,

• The second sensor activates and stops the conveyor. This step is necessary for the precise weighing of the boxes,

• A scale mechanism inside the blue conveyor measures the weight of the boxes. These data are used later in directing the process,

• If a 1.5 kg box arrives, the pneumatic separator transfers the box to the right conveyor, and when the sensor at the beginning of the right conveyor sees it, the pneumatic separator returns to its original position,

• If a 5 kg box arrives, the pneumatic separator transfers the box to the left conveyor, and when the sensor at the beginning of the left conveyor sees it, the pneumatic separator returns to its original position,

• If a box with a weight other than 1.5 or 5 kg arrives, the pneumatic separator transfers the box to the conveyor further ahead,

• The boxes are transferred to the palletizing system via the conveyor and lifted upwards,

• 1.5 kg boxes continuing from the right are counted in sets of 6 and pushed onto the pallet with a piston, the curtain opens, and the pallet descends one level,

• The pallet conveyor always feeds the pallet system,

• Then, 1.5 kg boxes are counted again in sets of 6 and placed on the pallet,

• When the pallet reaches the racking section, a sensor detects it, and the system starts working,

• The rail conveyor system takes the pallet and arranges them on the shelves,

• At the same time, the total box count, the number of pallets placed on the shelves, the weighed weight, the number of boxes transferred to the left, the number of boxes transferred forward, and the number of boxes transferred to the right can be monitored in real-time from the control panel,

• If desired, values can be reset from the control panel with the reset button,

• The operation can be stopped at any time using the "stop" button on the control panel.

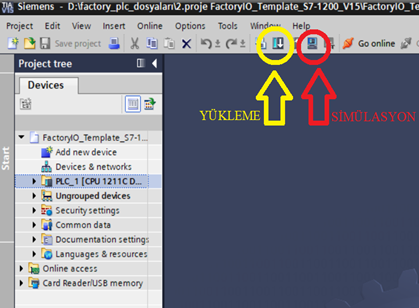

Connection Settings of PLC and Factory-io program

• Download the Factory I/O template file.

• Create the PLC program.

• Run the simulation in TIA Portal software.

• Then, create the system in the Factory I/O program.

• Go to the driver settings menu from the File menu.

• Choose Siemens S7-PLCSIM as the PLC type.

• Select 1200 PLC from the configuration settings.

• Then, click on "Connect" to establish a connection.

Tia Portal Software

Below is the Tia Portal software. The contact names in the Tia Portal must match the Factory-io program, otherwise it will not work.

Plc Tags and Data Block

Perfect

re

il